Torque tools: controlled tightening

On the strength of more than 71 years' experience acquired in the area of dynamometrics, SAM Outillage can propose the right tools to meet its customers' most exacting requirements. Whether it is for a specific application or for general use, you will find a suitable solution in the SAM range.

Controlled tightening of a screwed assembly: a necessity

The requirements in terms of safety, performance and quality, the use of new and increasingly technical, light and compact materials mean that manufacturers must have perfect control over their assemblies.

What are the needs in terms of controlled tightening?

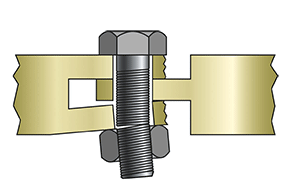

In an assembly, the various parts are held in place by means of screw + nut assemblies. However, these screw + nut assemblies are subjected to three major forms of stress:

- Excessive tightening

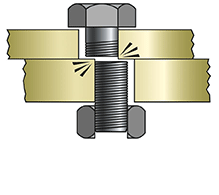

When the screw + nut assembly is subjected to great a force, the body of the screw tends to stretch to a point where, if it exceeds the steel's elastic limit, the deformation becomes permanent and comes close to its breaking point.

You must also take into account the resistance of the parts to be assembled, often lower than the elastic limit of the screw and than the operator's muscular strength, which is different from one person to another and may vary according to their degree of tiredness. - Vibrations

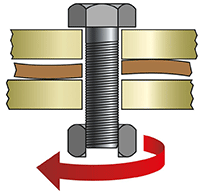

Most materials and machines used in industry are subjected to vibrations, a frequent cause of the loosening of insufficiently tightened screws.

- Temperature differencesWhen the parts are assembled at a given temperature and are then used at a different temperature, mechanical assemblies tend to "shift" and thus cause screws to loosen or even to break.

-> The solution: respect the tightening torque values using a torque wrench made by SAM Outillage

Only a torque wrench enables controlled tightening to a torque value determined according to the quality of the bolts, the parts to be assembled and the result to be obtained.

This regular tightening guarantees:

- Compliance with the applicable standards, recommendations and requirements

- Perfect sealing when tightening with seals

- Dependable and precise assemblies

- Uniform tightening

- Safe execution

Good tightening, tightening to the torque value

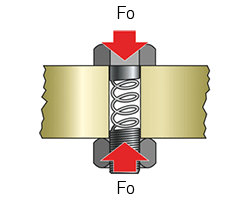

A screw acts on the assembly like a spring. The tension Fo usually adopted is at the most equal to 85% of the screw's elastic limit.

Fo calculated in Newtons.

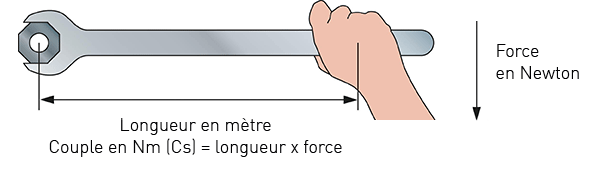

To obtain this tension force, you must tighten to the "torque value":

The torque value depends on:

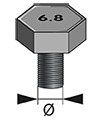

- the screw's diameter,

- the screw's quality class (etched onto the head of the screw).

3 modes of use

But 80 to 90% of this torque value is lost in the friction on the screw pitch, the head and the nut.

The assembly yield (μ) depends on the condition of the surfaces, the materials and the greasing quality.

What are the safety-related risks owing to poor tightening?

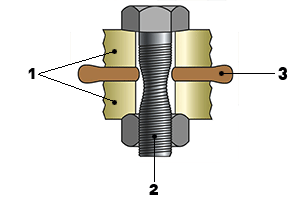

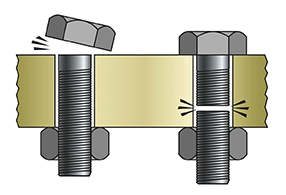

Insufficient tightening

Insufficient tightening may be the cause of bolt loosening.

Shearing owing to slippage

Unscrewing owing to vibrations

Seal too loose

What tightening torque should you apply?

There are three ways of determining the tightening torque to be applied...

determining the tightening torque valueExcessive tightening

On the contrary, excessive tightening can damage the screw and seal, and disrupt the system's dynamic functioning.

1. Seizing of the contact surfaces

2. Stretching of the screw beyond its elastic limit: the screw no longer plays its role as spring

3. Crushing of the seal

Breaking

Deformation