X-DRAINER®: drain the cooling circuit on all vehicles

The SAMX'DRAINER® is a device used for draining every type of cooling circuit. This device allows you to drain, check sealing, create a vacuum, fill the cooling circuit under negative pressure and temporarily store contaminated liquid. It can also be used to test valves on expansion tank plugs.

Why buy a SAM'X-DRAINER® cooling circuit drainer3 good reasons

- Increased productivity

- Protection of the environment

- Compatible with all types of vehicles, even hybrid and electric ones

INNOVATIONSpeeds up draining thanks to the special blower that can be connected to the drain screws.

Stand-aloneDrainage during idle time.

Totally stand-alone device: Just one operator needed.

Totally stand-alone device: Just one operator needed.

EnvironmentFloor protection: no workshop floor contamination possible.

SafetyOperator protection: no emanations of glycol, which is toxic for humans. No risk of burns.

TIME SAVINGSMaximum vehicle drainage time: 45 minutes.

Lifetime10 years: Designed and made in France.

ComfortFluid transfer within minutes: Double tank with fully pneumatic operation.

Totally silent device.

Functions on all vehicles: Negative pressure possible down to -0.9 bar. Ideal for hybrid vehicles.

Totally silent device.

Functions on all vehicles: Negative pressure possible down to -0.9 bar. Ideal for hybrid vehicles.

Productivity5 operations with just ONE machine: no accumulation of tools. All-in-one product.

No need to disconnect any hoses: connection via plugs or universal cone to work on all types of motor vehicle.

No need to disconnect any hoses: connection via plugs or universal cone to work on all types of motor vehicle.

Prevents musculoskeletal disorders:Improves working positions: no need to work with the "back bent".

Design and ergonomics carefully studied to avoid musculoskeletal disorders.

Design and ergonomics carefully studied to avoid musculoskeletal disorders.

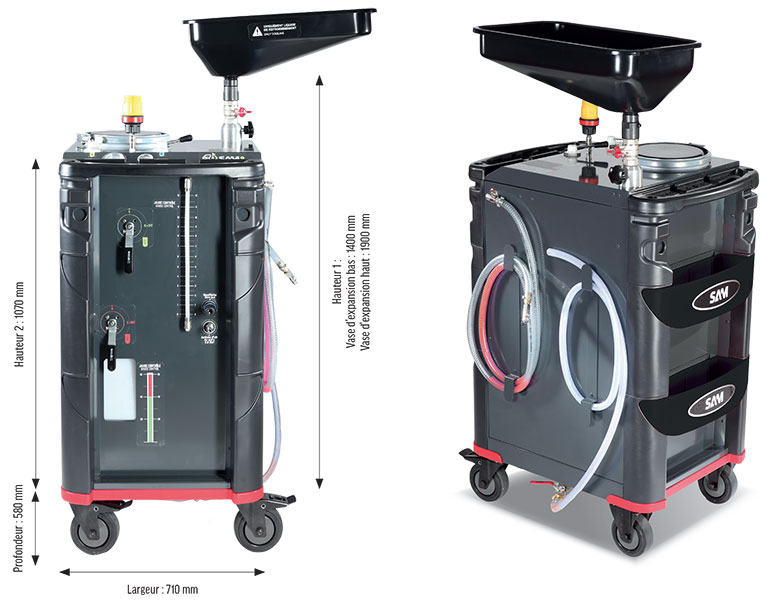

Characteristics of the cooling circuit drainer

- Mobile unit

- Can be used to drain, create a vacuum, check sealing, fill using a partial vacuum, bleed cooling circuits and recover contaminated liquid without any human intervention.

- It can also be used to test valves on expansion tank plugs.

- Tank containing the new liquid: 20L

- Intermediate recovery tank: 12 L

- 50L lower tank and gauge for measuring the extracted used liquid to respect the environment and gauge for measuring the extracted used liquid to respect the environment

- 15 L recovery funnel enabling gravity transfer if necessary.

- Connected directly to the expansion tank.

- Supplied with a universal plug and a rubber cone enabling connection to any type of motor vehicle.

- Powered by a compressed air supply: Minimum pressure 6.5 bar

- Approved under the EC machinery directive

- Empty weight: 57 kg.